Admixture Testing

Admixtures are materials added to the concrete before or during its mixing, with a view to modifjring one or more of the properties of concrete in the plastic or hardened state. An important feature of the majority of admixtures for concrete is that it is difficult to quantitatively evaluate the behaviour of the concrete under various possible circumstances. In recent time there has been a lot of development in the field of admixtures. Super plasticizers, both normal and retarding type, constitute a major group of admixtures used by site engineers now. Super plasticizers help in lowering the water/cement ratio so as to contribute to the enhancement of durability. Concrete admixture testing needs to be done to make sure it complies with the supplier's product specification and to make sure it satisfies the code requirements. Chemical Properties Of Admixtures Affect the Quality and Durability of Concrete.

Admixture testing shall be done before the use as specified in the project specification or the supplier. Some of the terms could be evaluated based on the supplier's specification.

Admixtures are materials added to the concrete before or during its mixing, with a view to modifjring one or more of the properties of concrete in the plastic or hardened state. An important feature of the majority of admixtures for concrete is that it is difficult to quantitatively evaluate the behaviour of the concrete under various possible circumstances. In recent time there has been a lot of development in the field of admixtures. Super plasticizers, both normal and retarding type, constitute a major group of admixtures used by site engineers now. Super plasticizers help in lowering the water/cement ratio so as to contribute to the enhancement of durability. Concrete admixture testing needs to be done to make sure it complies with the supplier's product specification and to make sure it satisfies the code requirements. Chemical Properties Of Admixtures Affect the Quality and Durability of Concrete.

Admixture testing shall be done before the use as specified in the project specification or the supplier. Some of the terms could be evaluated based on the supplier's specification.

Some of the Common Tests Conducted on Admixture include (as per IS 9103 & 6925)

1. Ash Content

1. Ash Content

2. pH Value

2. pH Value

3. Dry Material Content

3. Dry Material Content

4. Relative Density

4. Relative Density

5. Chloride

5. Chloride

Major Equipment's Used

1. Muffle Furnace

1. Muffle Furnace

2. Oven

2. Oven

3. Digital Weighing Balance

3. Digital Weighing Balance

4. pH Meter

4. pH Meter

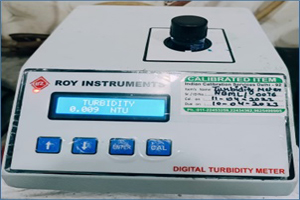

5. Turbidity Meter

5. Turbidity Meter

6. Hygrometer

6. Hygrometer