Paints Testing

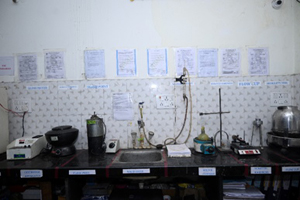

National Building material Lab Established Paint Testing and Surface Coating Lab. Our Lab Provide Paint Testing Facility to Various Government Semi Government and Private Ltd Organising Who Uses Paints In their Construction and Working Projects. Our laboratory Test Physical and Chemical Test of Paints In our laboratory Various kinds of paint are test such as enamel paint, Epoxy Primer based paints, Zinc Chromate Aluminium Paint Polyurethane Paints ready Mixed Paints Etc. Laboratory Equipped With various Testing Equipment's and Testing apparatus Which Required for Testing Of paint material and Also Wet Analysis of Paint Performed By Our Laboratory Our Client Are Indian Railway and Their Susidiary Company ,L&T,JSPL, Rites Limited, IRCON International, Private Ltd Sectors.

products like varnishes, enamels, pigments, printing inks and synthetic resins protect assets from corrosion. These are increasingly being used in automotive, engineering and consumer durable sectors. Paint testing can be done in a number of different ways. The fact of the matter is that many industries use several different paint testing methods in order to ensure accurate results. Paint should be tested in a wet form for particular properties but also in the dry form. Testing of paints generally falls into three categories: testing of the raw materials, testing of the finished product and performance testing using accelerated weathering and other simulation type methods of evaluation Coatings technologists deal with

interfaces of all classes' The purpose of paint testing is to help and ensure that the minimum requirements for ingredients and material characterization are met by the manufacturer on a batch basis, and to help ensure that the formulated product will provide satisfactory performance in the environment. Quality Analyst Experts Paint Testing Carried out through Properly Calibrated Testing Equipment's And Instruments To Avoid Error in Results. And Gain Accuracy in their Results. Testing is performed as per Standards Testing Procedure like IS 101,ASTM, ISO and RDSO Etc. and also Observe Quality Of paint is matching As per Client Requirement or Standards Specifications. And Proper Reporting Is done As per NABL Guidelines. And ISO: 17025

National Building material Lab Established Paint Testing and Surface Coating Lab. Our Lab Provide Paint Testing Facility to Various Government Semi Government and Private Ltd Organising Who Uses Paints In their Construction and Working Projects. Our laboratory Test Physical and Chemical Test of Paints In our laboratory Various kinds of paint are test such as enamel paint, Epoxy Primer based paints, Zinc Chromate Aluminium Paint Polyurethane Paints ready Mixed Paints Etc. Laboratory Equipped With various Testing Equipment's and Testing apparatus Which Required for Testing Of paint material and Also Wet Analysis of Paint Performed By Our Laboratory Our Client Are Indian Railway and Their Susidiary Company ,L&T,JSPL, Rites Limited, IRCON International, Private Ltd Sectors.

products like varnishes, enamels, pigments, printing inks and synthetic resins protect assets from corrosion. These are increasingly being used in automotive, engineering and consumer durable sectors. Paint testing can be done in a number of different ways. The fact of the matter is that many industries use several different paint testing methods in order to ensure accurate results. Paint should be tested in a wet form for particular properties but also in the dry form. Testing of paints generally falls into three categories: testing of the raw materials, testing of the finished product and performance testing using accelerated weathering and other simulation type methods of evaluation Coatings technologists deal with

interfaces of all classes' The purpose of paint testing is to help and ensure that the minimum requirements for ingredients and material characterization are met by the manufacturer on a batch basis, and to help ensure that the formulated product will provide satisfactory performance in the environment. Quality Analyst Experts Paint Testing Carried out through Properly Calibrated Testing Equipment's And Instruments To Avoid Error in Results. And Gain Accuracy in their Results. Testing is performed as per Standards Testing Procedure like IS 101,ASTM, ISO and RDSO Etc. and also Observe Quality Of paint is matching As per Client Requirement or Standards Specifications. And Proper Reporting Is done As per NABL Guidelines. And ISO: 17025

Some of the Common Tests Conducted on Paints include (as per IS, ASTM and ISO standards)

1. Consistency

2. Viscosity

3. Flash Point

4. Water Content

5. Gloss Value (at Specular 45?o & 60?o )

6. Scratch Hardness

7. Pencil Hardness

8. Pigment Content

9. Pull of Adhesion

10. Drying Time

11. Cross Cut Adhesion

12. Finish

13. Mass in Kg per 10 Liter

14. Protection against Corrosion under condition of condensation

15. Salt Spray

16. Dry Film Thickness

17. Flexibility and Adhesion after 48 Hours of Air Drying

18. Fineness of Grind

19. Volatile Matter

20. Volume solids

21. Accelerated Storage Stability

22. Impact Test

23. Iron Content (Fe2O3)

24. Wet Opacity

25. Zinc Chrome

26. Zinc Oxide

27. Pot Life