CONSTRUCTION MATERIAL TESTING Ramagundam

NATIONAL BUILDING MATERIAL LAB is known for providing one of the best Construction Material Testing Ramagundam; we can carry out all your building material testing requirements to include Physical, Mechanical & Chemical Properties. Our main goal is to provide the best Construction Material Testing Ramagundam for your Construction Projects.

NATIONAL BUILDING MATERIAL LAB is known for providing one of the best Construction Material Testing Ramagundam; we can carry out all your building material testing requirements to include Physical, Mechanical & Chemical Properties. Our main goal is to provide the best Construction Material Testing Ramagundam for your Construction Projects. Construction activities can range from building of roads, highways, building, dams etc. Now the foundation of any construction works hings on the use of Building Materials which include ent, steel, concrete, aggregate, soil, rock, fly ash, bricks, tilesher you are constructing any Infrastructure Residential, Commercial, Industrial Plants, the Materials used in your construction projects must need best quality regulations, standards and service life requirements.

Material you will choose affects the quality costs, sustainability & environmental impact of your construction project. that's why selecting the quality material is Essential. As we provide best Construction Material Testing Ramagundam, we will help you to choose the best quality of building materials for your project successfully completed and stay on track.

A qualified and experienced team of NABL makes sure that your requirement is rendered with absolute satisfaction in a timely manner. We use recognized relevant and updated standards to carry out specific activities to ensure their impartiality and competence thus providing confidence in the test results, inspection reports and certifications provided.

What is Construction Material Testing Ramagundam?

Construction Material Testing (CMT) services are a set of procedures that are used to evaluate the physical and mechanical properties of construction materials. Construction Material Testing Ramagundam are typically provided by National Building Material Testing Lab and may include tests such as compressive strength, tensile strength, and modulus of elasticity for concrete and masonry; and compression, shear strength, and modulus of elasticity for wood and other building materials. The results of these tests are used to ensure that the materials being used in a construction project meet the necessary specifications and codes, and that they are suitable for their intended use.Benefits of Construction Material Testing Ramagundam

Construction Material Testing services offer several benefits, including:Quality assurance: Construction Material Testing Ramagundam ensures that the materials used in a construction project meet the necessary specifications and codes, which helps to ensure the overall quality of the finished structure.

Compliance with regulations: Construction Material Testing Ramagundam is often required by building codes and regulations to ensure that materials meet safety standards and guidelines.

Early identification of problems: By identifying problems with materials early in the construction process, CMT services can help to prevent delays and additional costs caused by rework or material replacement.

Cost savings: By identifying issues early, CMT services can help to prevent costly mistakes and help ensure that a project is completed within budget.

Improved design and construction: CMT results can be used to optimize the design and construction of a structure, which can lead to better performance and durability.

Asset Management: CMT results can be used for the future maintenance and repair of the building.

National Building Material Lab Provides the Best Construction Material Testing Ramagundam

NBML is one of the top-ranked laboratories in our region providing reliable, accurate, test result the analysis of building materials have to be conducted as per various accepted standardized test methods include IS, ASTM, BIS,ISO Etc.. As the leading provider of Construction Material Testing Services Ramagundam our testing activities include physical & chemical test. NBML also conduct Field testing NDT inspections. We are working with Road Project (NHAI),Rail Project (RDSO),Commercial buildings and Housing Project.Applications Area of Construction Material Testing Services:

Construction Material Testing services have a wide range of applications and are used in various areas of construction, such as:Building construction: Testing of materials such as concrete, masonry, steel, and wood to ensure they meet the necessary specifications and codes.

Infrastructure construction: Testing of materials such as asphalt, soil, and aggregates to ensure they are suitable for use in roads, bridges, and other infrastructure projects.

Rehabilitation and repair: Testing of existing structures and materials to assess their condition and suitability for repair or retrofitting.

Quality Control on production line: On production line of construction materials like cement, bricks, blocks, tiles, glass, etc to check their compliance to standard and specification.

Environmental Construction: Testing of materials used in projects such as landfills, dams, and levees to ensure they can withstand the forces of nature.

Geotechnical Engineering: Testing of soil, rocks and other geomaterials for various properties such as strength, compressibility, shear strength, permeability etc. for foundation design and construction of buildings, roads, bridges and other structures.

Overall, Construction Material Testing services play a vital role in ensuring the safety and integrity of the structures we build and live in.

![Construction Material Testing Ramagundam - National Building Material Lab Construction Material Testing Ramagundam - National Building Material Lab]() CONSTRUCTION MATERIAL TESTING PARAMETERS

CONSTRUCTION MATERIAL TESTING PARAMETERS

LABORATORY TESTS

Physical Test |

Chemical Test |

Field Test & NDT (Non-Destructive Test) |

|

|

|

|

Material We Tested at Our Construction Material Testing Lab Ramagundam

![Construction Material Testing Ramagundam - National Building Material Lab Construction Material Testing Ramagundam - National Building Material Lab]() SOIL

SOIL

The ecosystem of the Earth is largely made up of soil. soil is formed by the combination of rock, organic matter and pieces of minerals, air and water. It is considered to be the skin of the earth's crust. the quality of soil varies depending on its composition, strength, and type. Poor quality of the soil is one the critical issues faced by builders. Make sure the area is adequate for planned infrastructure and the soil can support the weight of the intended building before beginning any development. With us by taking Construction Material Testing Ramagundam can avoid any kind of issues and mistakes with roads, Building etc.

The ecosystem of the Earth is largely made up of soil. soil is formed by the combination of rock, organic matter and pieces of minerals, air and water. It is considered to be the skin of the earth's crust. the quality of soil varies depending on its composition, strength, and type. Poor quality of the soil is one the critical issues faced by builders. Make sure the area is adequate for planned infrastructure and the soil can support the weight of the intended building before beginning any development. With us by taking Construction Material Testing Ramagundam can avoid any kind of issues and mistakes with roads, Building etc.The quality of the soil is judged by analyzing those properties which limit a planned use. Various soil and site factors need to be determined in order to check the limitations before constructing a building or a structure. Some of these include: surface texture, permeability, water table, Erosion hazard and depth of soil and bedrock.

![Construction Material Testing Ramagundam - National Building Material Lab Construction Material Testing Ramagundam - National Building Material Lab]() LABORATORY TEST ON SOIL

LABORATORY TEST ON SOIL

PHYSICAL ANALYSIS OF SOIL

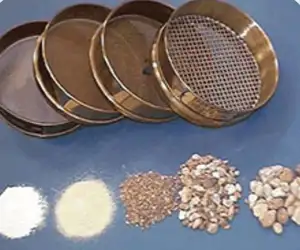

Grain Size Analysis

Attebrerge Limit

Specific Gravity Of Soil

Modified Proctor Compaction Test

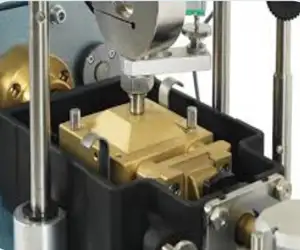

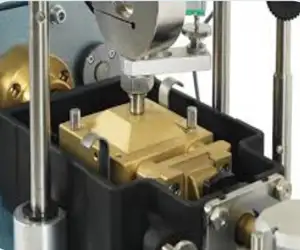

Direct Shear Test

CBR Test

Coefficient Of Permeability

Swelling Pressure

Consolidation Test

![Construction Material Testing Ramagundam - National Building Material Lab Construction Material Testing Ramagundam - National Building Material Lab]() CEMENT

CEMENT

The most important building material utilised in the building and construction sectors is cement. Its primary purpose is to give strength and form a bond with the other materials it is utilised with. We are providing Construction Material Testing Ramagundam to see if there is material alteration or loss while it is still solid. Methods of testing include heating cement to high temperatures to see if material is lost, checking compressive strength and fineness, among other things, to make sure they adhere to the necessary international standards. The construction industry uses a variety of cement kinds.

The most important building material utilised in the building and construction sectors is cement. Its primary purpose is to give strength and form a bond with the other materials it is utilised with. We are providing Construction Material Testing Ramagundam to see if there is material alteration or loss while it is still solid. Methods of testing include heating cement to high temperatures to see if material is lost, checking compressive strength and fineness, among other things, to make sure they adhere to the necessary international standards. The construction industry uses a variety of cement kinds.

PHYSICAL TEST ON CEMENT

Consistency Of Cement

Setting Time Of Cement

Fineness Test

Soundness Test

Compressive Strength Of Cement

![Construction Material Testing Ramagundam - National Building Material Lab Construction Material Testing Ramagundam - National Building Material Lab]() CHEMICAL ANALYSIS OF CEMENT

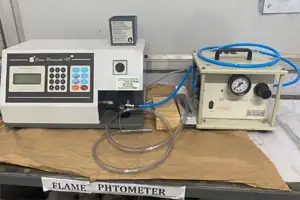

CHEMICAL ANALYSIS OF CEMENT

To properly serve its purpose in structure, cement used in construction needs to possess a number of characteristics. The engineer is certain that in the majority of circumstances, the cement performance will be satisfactory when these parameters fall within a specified range of standard values.

CHEMICAL TESTING PARAMETERS OF CEMENT

Calcium Oxide

Alumina

Insoluble Residue

Combine Iron Oxide

Loss On Ignition

Magnesia

Silica

Sulphuric Anhydride (As So3) % By Mass

Chloride

Total Alkali Content

![Construction Material Testing Ramagundam - National Building Material Lab Construction Material Testing Ramagundam - National Building Material Lab]() COARSE AGGREGATE

COARSE AGGREGATE

The construction industry relies heavily on aggregates, which can also be used for a variety of applications. Sand, gravel, crushed stone, and other coarse particle materials used in construction are all included in the wide category of "construction aggregate." Aggregate is also a component of composite materials like concrete and asphalt concrete. The aggregate acts as reinforcement to increase the overall strength of the composite material. They are primarily used to reinforce concrete, strengthening its framework and reducing the likelihood of cracks. Therefore, aggregates must be examined and looked over for quality before being used for building.

The construction industry relies heavily on aggregates, which can also be used for a variety of applications. Sand, gravel, crushed stone, and other coarse particle materials used in construction are all included in the wide category of "construction aggregate." Aggregate is also a component of composite materials like concrete and asphalt concrete. The aggregate acts as reinforcement to increase the overall strength of the composite material. They are primarily used to reinforce concrete, strengthening its framework and reducing the likelihood of cracks. Therefore, aggregates must be examined and looked over for quality before being used for building.

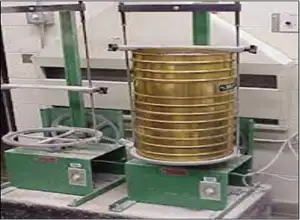

PHYSICAL TEST OF COARSE AGGREGATE

Impact Test On Aggregates

Sieve Analysis Of Coarse Aggregate

Specific Gravity & Water Absorption Test

CHEMICAL TESTING OF COARSE & FINE AGGREGATE

Determining the chemical make-up of aggregates and their sensitivity to various chemical environments is therefore crucial. Lab testing is required for this aggregates property. Analyze and test the chemical parameters in the lab to determine the behaviour of the substance. Chemical parameters for assessing coarse and fine aggregates are provided by our laboratory. It was necessary for various construction projects and road construction projects.

Alkali aggregate reactivity

1) Soundness Test

1) Soundness Test

2) Organic Impurities & Estimation of Deleterious materials

2) Organic Impurities & Estimation of Deleterious materials

3) Petrographical examination

3) Petrographical examination

![Construction Material Testing Ramagundam - National Building Material Lab Construction Material Testing Ramagundam - National Building Material Lab]() FINE AGGREGATE (SAND)

FINE AGGREGATE (SAND)

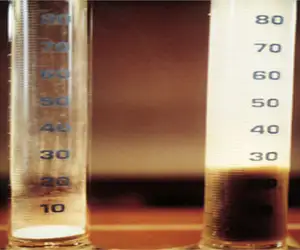

The tiny particles are smaller than 4.75 mm in size. That consists of aggregate particles less than 4.75 mm. Among the fine aggregates are materials like sand, silt, and clay. This may also include crushed gravel and stone that has been processed by machines. Usually, fine particles are used to concrete mixes to increase workability.

The tiny particles are smaller than 4.75 mm in size. That consists of aggregate particles less than 4.75 mm. Among the fine aggregates are materials like sand, silt, and clay. This may also include crushed gravel and stone that has been processed by machines. Usually, fine particles are used to concrete mixes to increase workability.

Grain Size Analysis

Specific Gravity & Water Absorption

Bulk Density (Loose & Compacted)

![Construction Material Testing Ramagundam - National Building Material Lab Construction Material Testing Ramagundam - National Building Material Lab]() MIX-DESIGN

MIX-DESIGN

A technique for choosing appropriate materials for concrete and analysing their relative proportions is called concrete mix design. The basis of a solid infrastructure is laid by a suitable concrete mix design. Creating the necessary strength and durability for the concrete construction requires a process of preparation known as concrete mix design. It's difficult to make a decent concrete mix because each ingredient has a different set of qualities. It is essential to test every component to ascertain both its physical characteristics and the project site's carrying capabilities.

A technique for choosing appropriate materials for concrete and analysing their relative proportions is called concrete mix design. The basis of a solid infrastructure is laid by a suitable concrete mix design. Creating the necessary strength and durability for the concrete construction requires a process of preparation known as concrete mix design. It's difficult to make a decent concrete mix because each ingredient has a different set of qualities. It is essential to test every component to ascertain both its physical characteristics and the project site's carrying capabilities.The ingredients to be tested: water, fine aggregate (sand), coarse aggregate, cement, admixtures reinforcement. concrete mix design is an extremely flexible building material which can be exclusive design for strength that may range from M-10 to M-100. the objective of preparing a design mix is to achieve a good quality concrete in the best Economic way.

High Strength Concrete

High Strength Concrete

Pumpable Concrete for RMC

Pumpable Concrete for RMC

Self Compacting concrete

Self Compacting concrete

Pavement Quality Concrete (PQC) For Road

Pavement Quality Concrete (PQC) For Road

High Volume fly-ash concrete

High Volume fly-ash concrete

Good Quality Concrete Imparts

Better Strength

Better Strength

Better durability

Better durability

Dense & homogeneous Concrete.

Dense & homogeneous Concrete.

![Construction Material Testing Ramagundam - National Building Material Lab Construction Material Testing Ramagundam - National Building Material Lab]() BRICK

BRICK

The construction blocks of any structural building are referred to as bricks. Consequently, each and every brick must be of high quality to prevent major structural damage to the building. The tests that follow are carried out by NBML to evaluate the bricks' quality. Bricks are given names based on their constituents, such as Fly ash Bricks, Burnt Clay Bricks, etc.

The construction blocks of any structural building are referred to as bricks. Consequently, each and every brick must be of high quality to prevent major structural damage to the building. The tests that follow are carried out by NBML to evaluate the bricks' quality. Bricks are given names based on their constituents, such as Fly ash Bricks, Burnt Clay Bricks, etc.

Dimension Test

Compressive Test

Water Absorption Test

Efflorescence Test

![Construction Material Testing Ramagundam - National Building Material Lab Construction Material Testing Ramagundam - National Building Material Lab]() MORTAR

MORTAR

Mortar is made by combining cement, lime, or both with water and sand. It is a paste that is used to connect construction materials like bricks and stones. It entirely covers the erratic spaces between the bricks by filling them. Additionally, stone walls can have patterns or colours added with mortar. Sand and water aggregates are the main ingredients in cement mortar, which is a material used in construction. The cement is hydrated with water to help hold the mixture together. Additionally, it can be used to smooth down the surfaces of brick and other masonry walls. When mortar is mixed, it becomes significantly thicker than concrete, which makes it perfect for use as an adhesive for construction materials. It hardens into a stone-like mass and distributes the load evenly over the bonding surfaces providing tight joints.

Mortar is made by combining cement, lime, or both with water and sand. It is a paste that is used to connect construction materials like bricks and stones. It entirely covers the erratic spaces between the bricks by filling them. Additionally, stone walls can have patterns or colours added with mortar. Sand and water aggregates are the main ingredients in cement mortar, which is a material used in construction. The cement is hydrated with water to help hold the mixture together. Additionally, it can be used to smooth down the surfaces of brick and other masonry walls. When mortar is mixed, it becomes significantly thicker than concrete, which makes it perfect for use as an adhesive for construction materials. It hardens into a stone-like mass and distributes the load evenly over the bonding surfaces providing tight joints.

Mortar testing Parameter

Mortar Consistency

Mortar Consistency

Mortar Compressive Strength (Field Prepared)

Mortar Compressive Strength (Field Prepared)

Mortar Compressive Strength (Laboratory Prepared)

Mortar Compressive Strength (Laboratory Prepared)

Mortar Aggregate ratio

Mortar Aggregate ratio

Water Retention

Water Retention

Air Content

Air Content

Flexural bond strength

Flexural bond strength

![Construction Material Testing Ramagundam - National Building Material Lab Construction Material Testing Ramagundam - National Building Material Lab]() TILES

TILES

Tiles are produced materials such as stone, ceramic, glass, or metal that is used in construction. Their primary use is for covering surfaces like walls, floors, and roofs. Based on the manufacturing method used and the intended use, tiles are divided into different categories. Additionally, they are grouped according to water absorption rates. Glass tiles, acid-resistant tiles, ceramic tiles, stone tiles, vitrified tiles, and concrete flooring tiles can all be evaluated for performance skillfully by NBML. For all types of tiles, we Provides Construction Material Testing Ramagundam, we offer testing facilities in accordance with their Standards.

Tiles are produced materials such as stone, ceramic, glass, or metal that is used in construction. Their primary use is for covering surfaces like walls, floors, and roofs. Based on the manufacturing method used and the intended use, tiles are divided into different categories. Additionally, they are grouped according to water absorption rates. Glass tiles, acid-resistant tiles, ceramic tiles, stone tiles, vitrified tiles, and concrete flooring tiles can all be evaluated for performance skillfully by NBML. For all types of tiles, we Provides Construction Material Testing Ramagundam, we offer testing facilities in accordance with their Standards.

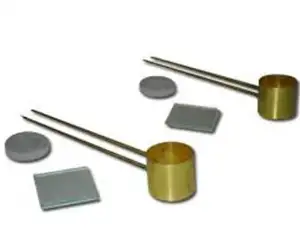

Testing Parameters of Tiles

Dimension

Dimension

Flexural strength

Flexural strength

Breaking strength

Breaking strength

Abrasion Resistance

Abrasion Resistance

Impact Resistance

Impact Resistance

Thermal Expansion

Thermal Expansion

Bulk density

Bulk density

Chemical resistance

Chemical resistance

Staining resistance

Staining resistance

![Construction Material Testing Ramagundam - National Building Material Lab Construction Material Testing Ramagundam - National Building Material Lab]() BITUMEN TESTING

BITUMEN TESTING

Bitumen is a mixture of polycyclic aromatic hydrocarbons that are primarily extremely condensed, highly viscous, black sticky, and completely soluble in carbon disulfide. After higher tractions like gas, petrol, kerosene, and diesel, etc. are removed from acceptable crude oil, it is mostly obtained as a residual product in petroleum refineries. Bitumen is a non-crystalline, dark-brown, viscous substance with sticky qualities that is either black or dark brown in colour. either naturally or by a refinery process, from petroleum crude.

Bitumen is a mixture of polycyclic aromatic hydrocarbons that are primarily extremely condensed, highly viscous, black sticky, and completely soluble in carbon disulfide. After higher tractions like gas, petrol, kerosene, and diesel, etc. are removed from acceptable crude oil, it is mostly obtained as a residual product in petroleum refineries. Bitumen is a non-crystalline, dark-brown, viscous substance with sticky qualities that is either black or dark brown in colour. either naturally or by a refinery process, from petroleum crude.

Testing Parameters of Bitumen

Bitumen content

Bitumen content

Bitumen penetration

Bitumen penetration

Flash Point

Flash Point

Softening point

Softening point

Paraffin wax

Paraffin wax

Loss on heating

Loss on heating

Water content

Water content

Ductility test

Ductility test

Bitumen Emulsion

Bitumen Emulsion

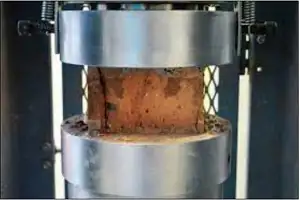

![Construction Material Testing Ramagundam - National Building Material Lab Construction Material Testing Ramagundam - National Building Material Lab]() DESTRUCTIVE TEST

DESTRUCTIVE TEST

Compressive Strength Concrete of Cube

For the IS 516 (pt.1/sec.1) 2021 durability test of concrete, NBML offers the art of the precise, accurate, and trustworthy testing service. The concrete cube test's compressive strength gives information about all of concrete's properties. One can determine whether or not concrete work has been done properly by using this one test. Numerous variables, including the water-cement ratio, cement strength, the quality of the raw materials used in the manufacturing of the concrete, quality control measures taken during production, etc., affect the compressive strength of concrete.

For the IS 516 (pt.1/sec.1) 2021 durability test of concrete, NBML offers the art of the precise, accurate, and trustworthy testing service. The concrete cube test's compressive strength gives information about all of concrete's properties. One can determine whether or not concrete work has been done properly by using this one test. Numerous variables, including the water-cement ratio, cement strength, the quality of the raw materials used in the manufacturing of the concrete, quality control measures taken during production, etc., affect the compressive strength of concrete.

![Construction Material Testing Ramagundam - National Building Material Lab Construction Material Testing Ramagundam - National Building Material Lab]() FLEXURAL TEST

FLEXURAL TEST

For the IS 516 (pt.1/sec.1) 2021 durability test of concrete, NBML offers the art of the precise, accurate, and trustworthy testing service. One indicator of concrete's tensile strength is flexural strength. It measures how well an unreinforced concrete slab or beam can withstand failure due to bending. Depending on the kind, size, and quantity of coarse aggregate used, flexural strength is roughly 10 to 20 percent of compressive strength.

For the IS 516 (pt.1/sec.1) 2021 durability test of concrete, NBML offers the art of the precise, accurate, and trustworthy testing service. One indicator of concrete's tensile strength is flexural strength. It measures how well an unreinforced concrete slab or beam can withstand failure due to bending. Depending on the kind, size, and quantity of coarse aggregate used, flexural strength is roughly 10 to 20 percent of compressive strength.

CONSTRUCTION MATERIAL TESTING PARAMETERS

CONSTRUCTION MATERIAL TESTING PARAMETERS

Soil

Soil