Metal Testing in Malegaon

A renowned pioneer in Metal Testing in Malegaon is called as NATIONAL BUILDING MATERIAL LAB. Both metal testing and NBML expert chemical and mechanical testing No matter what type of material you have—metal, nonmetal, or alloy—we have all the tools needed to analyse it both quantitatively and qualitatively. We excel at preparing test results and certified reports quickly, conveniently & economically.

A renowned pioneer in Metal Testing in Malegaon is called as NATIONAL BUILDING MATERIAL LAB. Both metal testing and NBML expert chemical and mechanical testing No matter what type of material you have—metal, nonmetal, or alloy—we have all the tools needed to analyse it both quantitatively and qualitatively. We excel at preparing test results and certified reports quickly, conveniently & economically.As the best Metal Testing in Malegaon, we have a team of highly motivated and skilled scientists working in our lab. In order to do a fast chemical analysis of metals, we are installing a brand-new SPECTROMAXx made in Germany. We also use more conventional approaches for investigating the required characteristics, such as wet chemical processes and instrumentation techniques.

What is Metal Testing?

Metal Testing services are a set of procedures that are used to evaluate the physical and mechanical properties of metal materials. These services typically include tests such as tensile testing, hardness testing, and impact testing to determine the strength, ductility, and toughness of a metal. Other tests such as chemical analysis, corrosion testing, and microstructure analysis can also be performed to determine the composition and quality of the metal. These tests are performed on various types of metals like Aluminium, Copper, Iron, Steel, Zinc, Nickel, etc.The results of these tests can be used in a number of ways, such as:

Quality Control: To ensure that the metal materials used in a project meet the necessary specifications and codes, and are suitable for their intended use.

Compliance: To ensure that metal materials and structures comply with industry standards and regulations, and meet safety and performance requirements.

Research and Development: To develop new metal materials or improve existing ones through testing and characterization.

Failure Analysis: To determine the cause of failure in a metal component or structure, and identify ways to prevent similar failures in the future.

Material Selection: To compare different metal materials and determine which one is the most suitable for a particular application.

Overall, Metal Testing in Malegaon plays a vital role in ensuring the quality, safety and reliability of metal-based products, structures and components.

National Building Material Lab Provides the Best Metal Testing in Malegaon

The most reliable updated instruments are well-equipped at NBML. We have a 1000-KN capacity universal testing machine (UTM) that is automated. We also promise to deliver the findings in the shortest timeframe and for the least amount of money while maintaining nearly perfect accuracy.Our promise to our clients to offer the best possible services and Metal Testing in Malegaon. We offer testing services for structural steel, metal, and other types of steel products. The NABL's scope applies to all tests. The tests are carried out in accordance with the necessary national or international standards, such as ASTM, ISO, IS, and others.

TESTING PARAMETER OF METAL

![Metal Testing in Malegaon - National Building Material Lab Metal Testing in Malegaon - National Building Material Lab]() MECHANICAL TEST

MECHANICAL TEST

Measuring the physical characteristics of components and raw materials can help you assess their durability and provide an understanding of how they will function in use. Your materials may be impacted by improper machining, poor material choice, and exposure, which could lead to expensive failures and recalls. As a have everything you require to give you the answers. Our Metal Testing in Malegaon is always done in accordance with IS, ASTM, and other standards. In order to ascertain the material specification and the material property of the application environment, testing can also be done in a variety of conditions as per the customer's demands, such as temperature, tension, compression, impact, and load.

MECHANICAL TESTING PARAMETER

![Metal Testing in Malegaon - National Building Material Lab Metal Testing in Malegaon - National Building Material Lab]() Tensile Test :- For tensile tests, we have a computerised universal testing machine (UTM) with a 1000 KN capacity. The resistance of a material to a static or gradually applied force is measured by a tensile test. In the testing apparatus, a machined specimen is put, and load is applied. Elongation is measured using a strain gauge or extensometer. Tensile strength is defined as the stress produced at the maximum applied force. The yield strength is the stress under which a certain amount of plastic defines how far the specimen can be stretched without breaking. Using a tensile yet, one can learn about a material's strength, stiffness, and ductility.

Tensile Test :- For tensile tests, we have a computerised universal testing machine (UTM) with a 1000 KN capacity. The resistance of a material to a static or gradually applied force is measured by a tensile test. In the testing apparatus, a machined specimen is put, and load is applied. Elongation is measured using a strain gauge or extensometer. Tensile strength is defined as the stress produced at the maximum applied force. The yield strength is the stress under which a certain amount of plastic defines how far the specimen can be stretched without breaking. Using a tensile yet, one can learn about a material's strength, stiffness, and ductility.

![Metal Testing in Malegaon - National Building Material Lab Metal Testing in Malegaon - National Building Material Lab]() Bend Test & Re-Bend Test :- The process of bend testing is used to assess the relative ductility of metal that is to be manufactured (often sheets, plates, or wire), as well as the soundness and toughness of metal. Typically, the specimen is bent over a mandrel with a predetermined diameter.

Bend Test & Re-Bend Test :- The process of bend testing is used to assess the relative ductility of metal that is to be manufactured (often sheets, plates, or wire), as well as the soundness and toughness of metal. Typically, the specimen is bent over a mandrel with a predetermined diameter.

![Metal Testing in Malegaon - National Building Material Lab Metal Testing in Malegaon - National Building Material Lab]() Hardness Testing :- Hardness testing evaluates a material's resistance to penetration and quantifies the indentation's permanent depth. Metal Testing in Malegaon is incredibly helpful in the material selection process since it produces a hardness value, which shows how easily a material can be machined and how well it will wear. Simply put, the harder the material is, while employing a fixed force and a specific indenter.

Hardness Testing :- Hardness testing evaluates a material's resistance to penetration and quantifies the indentation's permanent depth. Metal Testing in Malegaon is incredibly helpful in the material selection process since it produces a hardness value, which shows how easily a material can be machined and how well it will wear. Simply put, the harder the material is, while employing a fixed force and a specific indenter.

![Metal Testing in Malegaon - National Building Material Lab Metal Testing in Malegaon - National Building Material Lab]() Impact Test :- Engineering materials can be assessed for their toughness and notch sensitivity using the impact test. Metals' toughness is typically tested using this method. The impact of a heavy pendulum or hammer falling at a fixed distance at a predetermined speed causes the test specimen with notches to break. Metal Testing in Malegaon test gauges the amount of energy the fragmented specimen has absorbed.

Impact Test :- Engineering materials can be assessed for their toughness and notch sensitivity using the impact test. Metals' toughness is typically tested using this method. The impact of a heavy pendulum or hammer falling at a fixed distance at a predetermined speed causes the test specimen with notches to break. Metal Testing in Malegaon test gauges the amount of energy the fragmented specimen has absorbed.

I. CHARPY IMPACT TEST :- A "V" or "U" Notch is used to mill a test specimen to a 10 mm X 10 mm (full size) cross section. Where the material thickness is constrained, sub-size specimens are used. At cryogenic temperatures, specimens can be tested.

II. IZOD IMPACT TEST :- The test sample is made of machined steel and has a square, round section with one, two, or three notches. It is clamped vertically on the anvil with the notch facing the hammer.

![Metal Testing in Malegaon - National Building Material Lab Metal Testing in Malegaon - National Building Material Lab]() Extensometer (0.2 % proof stress)

Extensometer (0.2 % proof stress)

![Metal Testing in Malegaon - National Building Material Lab Metal Testing in Malegaon - National Building Material Lab]() Pull-out Test

Pull-out Test

INSTRUMENTS FACILITIES:-

![Metal Testing in Malegaon - National Building Material Lab Metal Testing in Malegaon - National Building Material Lab]() Universal Testing Machine.

Universal Testing Machine.

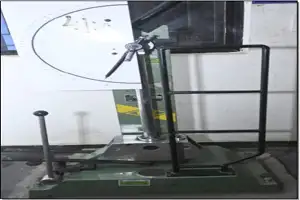

![Metal Testing in Malegaon - National Building Material Lab Metal Testing in Malegaon - National Building Material Lab]() Impact Testing Machine

Impact Testing Machine

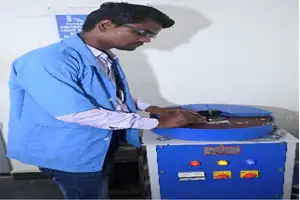

![Metal Testing in Malegaon - National Building Material Lab Metal Testing in Malegaon - National Building Material Lab]() Rockwell Hardness Testing Machine

Rockwell Hardness Testing Machine

MECHANICAL TESTING PARAMETER

Tensile Test :- For tensile tests, we have a computerised universal testing machine (UTM) with a 1000 KN capacity. The resistance of a material to a static or gradually applied force is measured by a tensile test. In the testing apparatus, a machined specimen is put, and load is applied. Elongation is measured using a strain gauge or extensometer. Tensile strength is defined as the stress produced at the maximum applied force. The yield strength is the stress under which a certain amount of plastic defines how far the specimen can be stretched without breaking. Using a tensile yet, one can learn about a material's strength, stiffness, and ductility.

Tensile Test :- For tensile tests, we have a computerised universal testing machine (UTM) with a 1000 KN capacity. The resistance of a material to a static or gradually applied force is measured by a tensile test. In the testing apparatus, a machined specimen is put, and load is applied. Elongation is measured using a strain gauge or extensometer. Tensile strength is defined as the stress produced at the maximum applied force. The yield strength is the stress under which a certain amount of plastic defines how far the specimen can be stretched without breaking. Using a tensile yet, one can learn about a material's strength, stiffness, and ductility.

Bend Test & Re-Bend Test :- The process of bend testing is used to assess the relative ductility of metal that is to be manufactured (often sheets, plates, or wire), as well as the soundness and toughness of metal. Typically, the specimen is bent over a mandrel with a predetermined diameter.

Bend Test & Re-Bend Test :- The process of bend testing is used to assess the relative ductility of metal that is to be manufactured (often sheets, plates, or wire), as well as the soundness and toughness of metal. Typically, the specimen is bent over a mandrel with a predetermined diameter.

Hardness Testing :- Hardness testing evaluates a material's resistance to penetration and quantifies the indentation's permanent depth. Metal Testing in Malegaon is incredibly helpful in the material selection process since it produces a hardness value, which shows how easily a material can be machined and how well it will wear. Simply put, the harder the material is, while employing a fixed force and a specific indenter.

Hardness Testing :- Hardness testing evaluates a material's resistance to penetration and quantifies the indentation's permanent depth. Metal Testing in Malegaon is incredibly helpful in the material selection process since it produces a hardness value, which shows how easily a material can be machined and how well it will wear. Simply put, the harder the material is, while employing a fixed force and a specific indenter.

Impact Test :- Engineering materials can be assessed for their toughness and notch sensitivity using the impact test. Metals' toughness is typically tested using this method. The impact of a heavy pendulum or hammer falling at a fixed distance at a predetermined speed causes the test specimen with notches to break. Metal Testing in Malegaon test gauges the amount of energy the fragmented specimen has absorbed.

Impact Test :- Engineering materials can be assessed for their toughness and notch sensitivity using the impact test. Metals' toughness is typically tested using this method. The impact of a heavy pendulum or hammer falling at a fixed distance at a predetermined speed causes the test specimen with notches to break. Metal Testing in Malegaon test gauges the amount of energy the fragmented specimen has absorbed.

I. CHARPY IMPACT TEST :- A "V" or "U" Notch is used to mill a test specimen to a 10 mm X 10 mm (full size) cross section. Where the material thickness is constrained, sub-size specimens are used. At cryogenic temperatures, specimens can be tested.

II. IZOD IMPACT TEST :- The test sample is made of machined steel and has a square, round section with one, two, or three notches. It is clamped vertically on the anvil with the notch facing the hammer.

Extensometer (0.2 % proof stress)

Extensometer (0.2 % proof stress)

Pull-out Test

Pull-out Test

INSTRUMENTS FACILITIES:-

Universal Testing Machine.

Universal Testing Machine.

Impact Testing Machine

Impact Testing Machine

Rockwell Hardness Testing Machine

Rockwell Hardness Testing Machine

UNIVERSAL TESTING MACHINE

IMPACT AND HARDNESS TESTING & EQUIPMENTS

![Metal Testing in Malegaon - National Building Material Lab Metal Testing in Malegaon - National Building Material Lab]() CHEMICAL TEST BY SPECTROMAXx

CHEMICAL TEST BY SPECTROMAXx

One of the well-known companies that provides Spectro chemical testing for different types of metals & alloys of engineering materials is National Building Material Lab as well as we are top provider of Metal Testing in Malegaon. This facilitates research into the test materials' varied chemical characteristics. We have a German-made SPECTROMAXx system installed, which can examine both ferrous and non-ferrous metal.

One of the well-known companies that provides Spectro chemical testing for different types of metals & alloys of engineering materials is National Building Material Lab as well as we are top provider of Metal Testing in Malegaon. This facilitates research into the test materials' varied chemical characteristics. We have a German-made SPECTROMAXx system installed, which can examine both ferrous and non-ferrous metal. It has incredibly simple operation. All operational parameters are independently monitored by the SPECTROMAXx arc/spark OES metal analyzer. Based on the provided sample attributes, it dynamically calculates the necessary measurement time and even indicates when the spark stand needs to be cleaned depending on the type of samples being investigated.

Its spark OES technology is dependable and extremely potent, making it the most extensively used method in the field of solid-state analysis of metals and alloys. Its appeal is a result of its quick speed. It is great to use since it does not require sample dissolution and because it produces a huge amount of sample analysis output, 400 to 500 samples can be analysed in a single day. These advanced tools provide multi-element analysis and are quite sensitive. In comparison to the conventional wet analytical approach, it is also time and money efficient.

As a Metal Testing in Malegaon, our testing engineers are skilled professionals that produce accurate results. We possess a wide variety of certified reference material (CRM) to cover the whole spectrum of metals, including manganese BS193, low alloy steel (MS steel) 458/2, aluminium steel A96063, and stainless steel SS 1962. Nearly every known element in the periodic table can be analysed qualitatively and quantitatively by NBML. Spectro examination of nitrogen and all metal components, including C, S, P, Mn, and Si, may be performed with great accuracy since we utilise internationally recognised reference material.

SPECTRO CHEMICAL ANALYSIS

Mild steel

Mild steel

Stainless Steel

Stainless Steel

Aluminum

Aluminum

Cast Iron

Cast Iron

![Metal Testing in Malegaon - National Building Material Lab Metal Testing in Malegaon - National Building Material Lab]() METALLOGRAPHY TESTING

METALLOGRAPHY TESTING

Metallography testing facilities are just one of the exact testing services that National Building Material Lab provides. Metallography is the discipline of science that uses microscopic methods to explore the structure and behaviour of metals and alloys. The primary goal of doing metallographic tests is to look at the microstructure of any sample of a metal or alloy. By using a light optical or scanning electron microscope, the three-dimensional arrangement of atomic elements ranging from 1 pm to 1 mm is investigated.

Metallography testing facilities are just one of the exact testing services that National Building Material Lab provides. Metallography is the discipline of science that uses microscopic methods to explore the structure and behaviour of metals and alloys. The primary goal of doing metallographic tests is to look at the microstructure of any sample of a metal or alloy. By using a light optical or scanning electron microscope, the three-dimensional arrangement of atomic elements ranging from 1 pm to 1 mm is investigated.Phase transition, volume fraction, grain size, depth banding, non-metallic inclusion in steel, porosity cross contamination, and a number of other intriguing characteristics are studied within the microstructure category. The microstructure denotes the mechanical characteristics, such as ductility, influence, toughness, and corrosion resistance. Because understanding and controlling behaviour of metals and alloys requires a thorough understanding of their microstructure, NBML provides Metal Testing in Malegaon that support quality control, failure analysis, and research and development.

The metallurgists at NBML are highly skilled in the metallographic preparation and examination needed to assess the properties of metals. They have a high level of expertise in evaluating the heat treatment state, microstructure, and forming procedure of a certain material. The team conducts macro- and micro-examinations, including weld examination, case depth and decarburization measurement, micro-hardness testing, and coating/plating evaluation.

![Metal Testing in Malegaon - National Building Material Lab Metal Testing in Malegaon - National Building Material Lab]() METALLOGRAPHY TEST AT NBML

METALLOGRAPHY TEST AT NBML

Micro-Examination : This is done on samples that have been either mounted on a resin mould or cut to size. These samples are polished to a smooth finish, often using a one-micron diamond paste, and are normally etched in the proper chemical solution before being examined under the metallurgical microscope. The most frequent use of micro-examination is to evaluate the material's structure, while it can be used for a variety of other applications as well. In addition to micro-examinations, several standard procedures, such as phase counts or particle size assessments, are carried out.

Macro-Examinations : A specimen is etched during macro-etching, and macro-structural analysis is performed at low magnifications. It is a method that is widely used to assess steel goods like billets, bars, blooms, and forgings. For both carbon and low alloy steels, there are many methods for evaluating a steel specimen using a graded series of images that demonstrate the occurrence of specific circumstances. Depending on the type of investigation, a variety of different etching reagents may be utilised. Because of differences in chemical composition, manufacturing processes, heat treatment, and many other factors, steels respond differently to etching reagents.

Polished and etched cross-sections of welded material are also subjected to macro-examinations. The weld run sequence, which is essential for weld procedure qualifications exams, is one of the elements that can be determined throughout the examination. In addition, the sample's flaws are examined for conformance with applicable criteria. Slag, porosity, a lack of weld penetration, a lack of sidewall fusion, and an unsatisfactory weld profile are some of the characteristics seen in this kind of study. Such flaws can be detected procedurally using magnifications up to 20X or a conventional visual check. A photomicrograph, which is a common practice, is a photograph of the part that serves as a permanent record.

Weld Examination : There are various ways to evaluate welds using metallographic and one of them is metal testing and we provide Metal Testing in Malegaon. Weld deposits can be visually inspected for significant flaws such porosity or a lack of fusion defects in its most basic form. On a smaller scale, the study might take the shape of a phase balance analysis of the weld cap or weld root, or it might even involve looking for non-metallic or third phase precipitates. Determine the causes of subpar mechanical test results by looking at weld development patterns.

Case Depth : Case Hardening is the process of hardening ferrous materials so that the surface layer, also known as the case, is significantly harder than the other materials (known as the core). Carburizing, nitriding, carbonitriding, cyaniding, induction, and flame hardening are used to manage this process. These procedures have an impact on the mechanical qualities and chemical composition. The suitable methodology is chosen depending on specific requirements and can be chemical, mechanical, or optical for determining case depth.

Decarburization Measurement : Decarburization measurement is a technique used to identify changes brought on by carburization in the microstructure, hardness, or carbon content of steel sections. A consistent microstructure, hardness, or carbon content of the specimen interior are observed to estimate the depth. This technique finds carbon content surface losses brought on by heating at high temperatures.

Evaluation of Coating or Plating : The main purpose of coating or plating is to protect the substrate. The performance of the coating or plating is significantly influenced by thickness. The specimen has a section that has been cut off, mounted transversely, and processed using methods that are acceptable or appropriate. An optical microscope is used to gauge the cross section's thickness. The evaluation of plating can be aided by thickness measurements, surface analyses, and cross-sectional metallographic studies of substrates with plating.

Grain Size Determination : In order to establish a scale for grain size, ASTM E112 shows charts with outline grain structures for various dimensions. These universally accepted standards range from ASTM NO. 00 (very coarse) to 10 (very fine). A material's grain size is important as it affects its mechanical properties. In most materials, a refined grain structure gives enhanced toughness, and alloying elements are deliberately added during the steel-making process to assist with grain refinement. Grain size is determined from a polished and etched sample, using optical microscopy at a magnification of 100X or 500X.

Macro-Examinations : A specimen is etched during macro-etching, and macro-structural analysis is performed at low magnifications. It is a method that is widely used to assess steel goods like billets, bars, blooms, and forgings. For both carbon and low alloy steels, there are many methods for evaluating a steel specimen using a graded series of images that demonstrate the occurrence of specific circumstances. Depending on the type of investigation, a variety of different etching reagents may be utilised. Because of differences in chemical composition, manufacturing processes, heat treatment, and many other factors, steels respond differently to etching reagents.

Polished and etched cross-sections of welded material are also subjected to macro-examinations. The weld run sequence, which is essential for weld procedure qualifications exams, is one of the elements that can be determined throughout the examination. In addition, the sample's flaws are examined for conformance with applicable criteria. Slag, porosity, a lack of weld penetration, a lack of sidewall fusion, and an unsatisfactory weld profile are some of the characteristics seen in this kind of study. Such flaws can be detected procedurally using magnifications up to 20X or a conventional visual check. A photomicrograph, which is a common practice, is a photograph of the part that serves as a permanent record.

Weld Examination : There are various ways to evaluate welds using metallographic and one of them is metal testing and we provide Metal Testing in Malegaon. Weld deposits can be visually inspected for significant flaws such porosity or a lack of fusion defects in its most basic form. On a smaller scale, the study might take the shape of a phase balance analysis of the weld cap or weld root, or it might even involve looking for non-metallic or third phase precipitates. Determine the causes of subpar mechanical test results by looking at weld development patterns.

Case Depth : Case Hardening is the process of hardening ferrous materials so that the surface layer, also known as the case, is significantly harder than the other materials (known as the core). Carburizing, nitriding, carbonitriding, cyaniding, induction, and flame hardening are used to manage this process. These procedures have an impact on the mechanical qualities and chemical composition. The suitable methodology is chosen depending on specific requirements and can be chemical, mechanical, or optical for determining case depth.

Decarburization Measurement : Decarburization measurement is a technique used to identify changes brought on by carburization in the microstructure, hardness, or carbon content of steel sections. A consistent microstructure, hardness, or carbon content of the specimen interior are observed to estimate the depth. This technique finds carbon content surface losses brought on by heating at high temperatures.

Evaluation of Coating or Plating : The main purpose of coating or plating is to protect the substrate. The performance of the coating or plating is significantly influenced by thickness. The specimen has a section that has been cut off, mounted transversely, and processed using methods that are acceptable or appropriate. An optical microscope is used to gauge the cross section's thickness. The evaluation of plating can be aided by thickness measurements, surface analyses, and cross-sectional metallographic studies of substrates with plating.

Grain Size Determination : In order to establish a scale for grain size, ASTM E112 shows charts with outline grain structures for various dimensions. These universally accepted standards range from ASTM NO. 00 (very coarse) to 10 (very fine). A material's grain size is important as it affects its mechanical properties. In most materials, a refined grain structure gives enhanced toughness, and alloying elements are deliberately added during the steel-making process to assist with grain refinement. Grain size is determined from a polished and etched sample, using optical microscopy at a magnification of 100X or 500X.

MECHANICAL TEST

MECHANICAL TEST